Tanzania Waste Incinerator Market Report: Characteristics, Demand Trends, and Applicability of Modern Incineration Solutions

1. Overview of Tanzania’s Waste Management Landscape

Tanzania, with major cities such as Dar es Salaam, Dodoma, Arusha, Mwanza, and Zanzibar, is experiencing rapid population growth and expanding public-health infrastructure. These factors significantly increase the amount of municipal, biomedical, industrial, and community-generated waste. Many regions still rely on open dumping or uncontrolled burning, especially in peri-urban zones such as Temeke, Ilala, and Kinondoni, creating long-term environmental and public health challenges.

The Government of Tanzania―supported by institutions including the United Nations, WHO, UNDP, and numerous humanitarian agencies―has been promoting safer and more compliant waste-disposal strategies. Incineration technology has therefore become a key component in national and donor-funded waste-management planning.

2. Key Market Characteristics

The waste incinerator market in Tanzania displays several notable structural features:

-

Mixed and high-moisture waste streams, particularly in Dar es Salaam and coastal regions.

-

Significant medical waste volume from hospitals in Dodoma, Arusha, Morogoro, and Mwanza.

-

Decentralized health facilities, including rural clinics across Kilimanjaro, Tanga, and Shinyanga, which require compact and easily operated incinerators.

-

Increasing environmental compliance, influenced by global health programs, UN-backed tenders, and institutional procurement standards.

These characteristics create consistent demand for engineered systems capable of stable combustion, low emissions, and reliable performance in hot, humid, or remote environments.

3. Market Demand and Emerging Trends

Multiple drivers are shaping the growth trajectory of Tanzania’s incinerator market:

-

Healthcare modernization

Expansion of regional hospitals, including facilities in Arusha and Mwanza, increases the need for compliant biomedical waste destruction. -

Humanitarian response and refugee-support operations

UN agencies working in Kigoma, Kasulu, and Tanga require standardized incineration solutions for field clinics, temporary settlements, and emergency medical operations. -

Urbanization and industrialization

Rapid growth in Dar es Salaam generates large volumes of mixed municipal waste, pushing local authorities to explore high-capacity, fuel-efficient incinerators. -

Environmental and regulatory reinforcement

Donor-funded programs emphasize emissions control, ash handling safety, and consistent high-temperature operation.

4. Suitability of Incineration Technology for Tanzania’s Local Conditions

Tanzania’s waste composition and climate conditions require incinerator systems with:

-

Secondary combustion capability for complete burnout of low-calorific or wet waste.

-

Diesel, LPG, or natural gas burners to stabilize combustion when moisture content is high.

-

Top-loading or batch-loading chambers suitable for community waste, animal waste, or large medical waste bags.

-

Mobile or containerized solutions that reduce civil-works requirements in rural districts.

These attributes correspond directly to the systems often deployed by UN missions and NGO logistics teams operating across East Africa.

5. HICLOVER Incinerators: Strengths for the Tanzanian Market

HICLOVER provides a range of incineration technologies that align with Tanzania’s operational requirements:

-

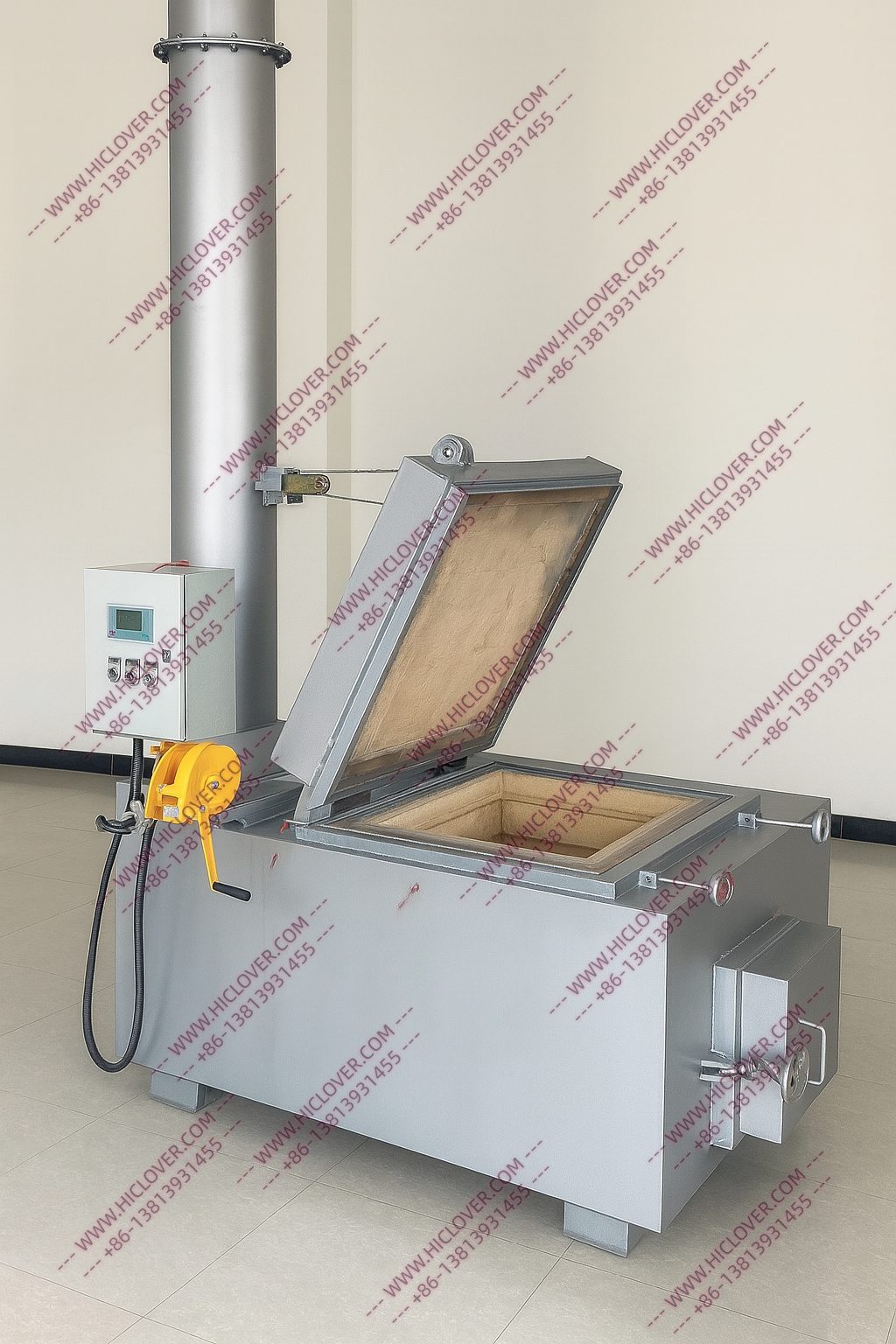

Top-loading incinerators suitable for bulky municipal waste in cities such as Dar es Salaam and Mwanza.

-

Medical waste models with multi-chamber combustion, ideal for hospitals in Dodoma, Arusha, and Morogoro.

-

Containerized mobile incinerators, preferred by NGOs, refugee-camp operators, and UN field missions.

-

Dry and wet gas-cleaning systems, supporting projects with higher emissions-control requirements.

-

Durable refractory structures and PLC-controlled burners, essential for long-term operation under demanding field conditions.

To support SEO structure, the following keyword-linked references point to your HICLOVER domain:

-

medical waste incinerator in Tanzania

-

top-loading waste incinerator

-

containerized incinerator solution

-

solid waste incinerator system

-

Tanzania waste treatment equipment

All links remain within the HICLOVER ecosystem and support keyword relevance.

6. Additional Highlight: Waste Treatment in Tanzania’s Coastal and Island Zones

Coastal cities―especially Dar es Salaam and Zanzibar―face unique environmental sensitivities. Tourism, fishing industries, and densely populated waterfront districts require stringent waste handling to protect coastal ecosystems. Incinerators designed for rapid ignition, reduced emissions, and minimal odor are especially valuable in locations where proximity to residential areas and marine habitats requires tighter operational control.

7. Market Outlook

Tanzania’s incinerator market is expected to expand steadily due to:

-

Continued investment in national and district-level healthcare infrastructure.

-

Growing involvement of the United Nations, especially in public-health projects and humanitarian logistics.

-

Rising environmental awareness among local authorities and development partners.

-

Increased demand for mobile systems capable of serving dispersed rural populations.

-

Government support for regulated and safe medical waste treatment.

These conditions position Tanzania as a high-potential and stable market for modern waste incineration technology.

Tanzania’s evolving waste-management framework presents strong demand for reliable, compliant, and adaptable incinerator solutions. From the urban centers of Dar es Salaam, Dodoma, and Arusha to remote communities across Kigoma and Tanga, engineered incineration systems offer a practical path toward safe waste destruction.

HICLOVER’s versatile product range―with top-loading options, medical-grade combustion systems, and mobile containerized units―aligns with both government and UN procurement requirements. Their technical durability and operational flexibility make them well suited to long-term waste-management strategies in Tanzania.

2025-12-11/14:29:51

|

Incinerator Items/Model |

HICLOVER TS100(PLC)

|

|

Burn Rate (Average) |

100kg/hour |

|

Feed Capacity(Average) |

150kg/feeding |

|

Control Mode |

PLC Automatic |

|

Intelligent Sensor |

Continuously Feeding with Worker Protection |

|

High Temperature Retention(HTR) |

Yes (Adjustable) |

|

Intelligent Save Fuel Function |

Yes |

|

Primary Combustion Chamber |

1200Liters(1.2m3) |

|

Internal Dimensions |

120x100x100cm |

|

Secondary Chamber |

600L |

|

Smoke Filter Chamber |

Yes |

|

Feed Mode |

Manual |

|

Burner Type |

Italy Brand |

|

Temperature Monitor |

Yes |

|

Temperature Thermometer |

Corundum Probe Tube, 1400℃Rate. |

|

Temperature Protection |

Yes |

|

Automatic Cooling |

Yes |

|

Automatic False Alarm |

Yes |

|

Automatic Protection Operator(APO) |

Yes |

|

Time Setting |

Yes |

|

Progress Display Bar |

3.7 in” LCD Screen |

|

Oil Tank |

200L |

|

Chimney Type |

Stainless Steel 304 |

|

1st. Chamber Temperature |

800℃–1000℃ |

|

2nd. Chamber Temperature |

1000℃-1300℃ |

|

Residency Time |

2.0 Sec. |

|

Gross Weight |

7000kg |

|

External Dimensions |

270x170x190cm(Incinerator Main Body) |

|

Burner operation |

Automatic On/Off |

|

Dry Scrubber |

Optional |

|

Wet Scrubber |

Optional |

|

Top Loading Door |

Optional |

|

Asbestos Mercury Material |

None |

|

Heat Heart Technology(HHT) |

Optional |

|

Dual Fuel Type(Oil&Gas) |

Optional |

|

Dual Control Mode(Manual/Automatic) |

Optional |

|

Temperature Record |

Optional |

|

Enhanced Temperature Thermometer |

Optional |

|

Incinerator Operator PPE Kits |

Optional |

|

Backup Spare Parts Kits |

Optional |

|

Mobile Type |

Optional:Containerized/Trailer/Sledge Optional |